Nine years after commissioning a SigmaLine, Rodona in Pamplona installed the SigmaLine III, the second digital book block system from Muller Martini – underpinning its leading position in the Spanish digital market.

“Spain tends to still be an offset country,” says Alberto Senosiain. “This is because inkjet was initially badmouthed and treated stepmotherly in our country. But that has changed in recent years because digital printing has numerous plus points. Firstly, the range of papers that can be processed with inkjet technology has become increasingly broad. Secondly, print quality has increased significantly. Thirdly, there are fewer errors because fewer people are involved in the optimized production process and there is less manual intervention. And fourth, our customers have logistical advantages: they can plan their production better, and thanks to our fast turnaround of medium and small production orders, they don’t have to manage large warehouses or dispose of unsold books – because we produce exactly as many copies as customers need.”

Spain’s digital pioneer

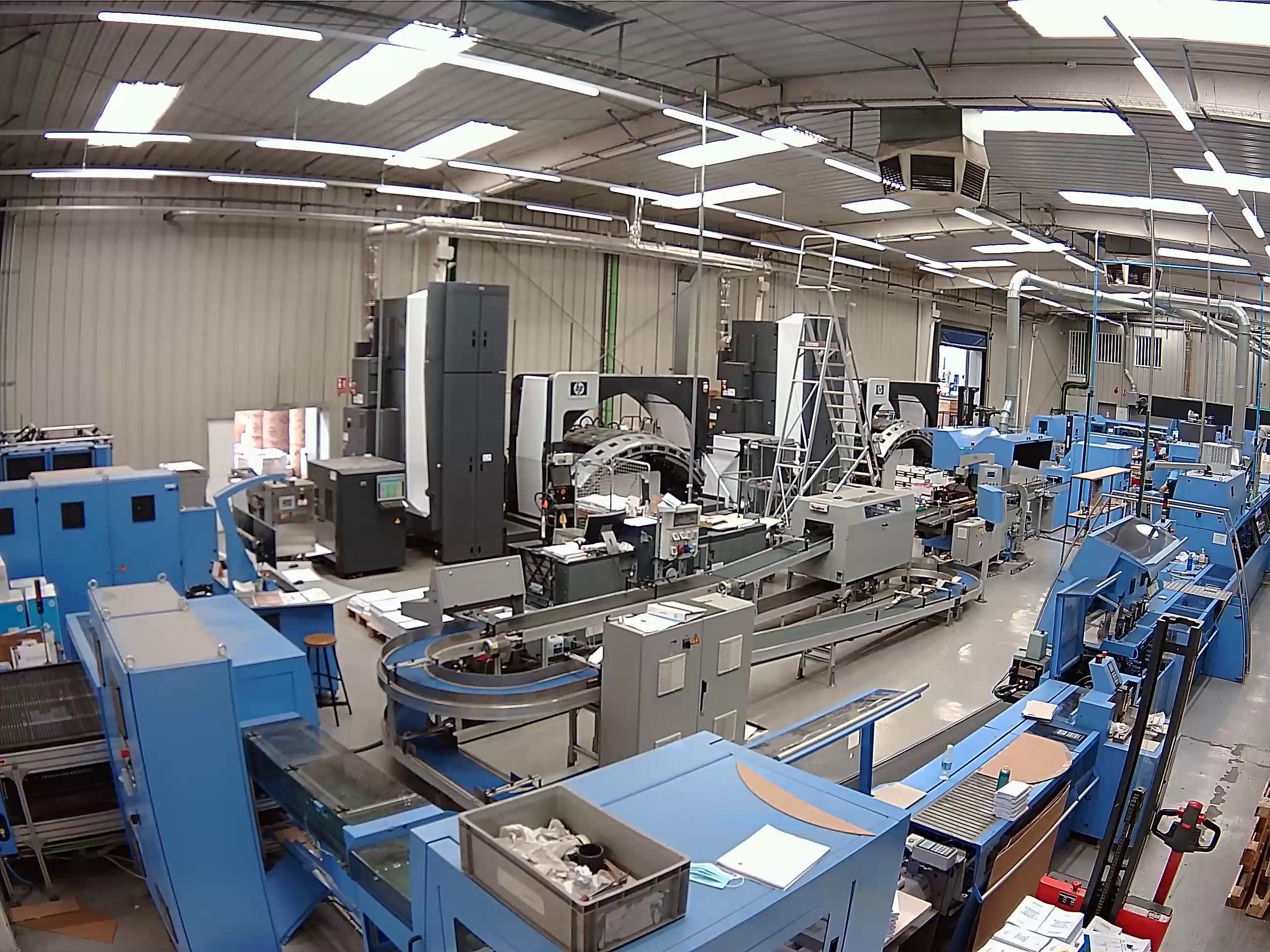

This trend is, of course, entirely to the liking of Rodona’s co-owner and managing director. After all, his company, which employs 25 people – normally working two shifts and three shifts at peak times – is one of Spain’s pioneers in inkjet rotary printing in this segment and has focused exclusively on digital printing for over a decade. In 2013, Rodona commissioned a complete SigmaLine with HP T300 press and Acoro A5 perfect binder as a world premiere and has since been producing inline softcover books in the shortrun segment in a highly productive manner.

Alberto Senosiain puts the term “short run” into perspective: “Medium runs are a better description. We usually start at 100 and produce up to 5000 copies per title. The average per job is between 400 and 500 copies. Book-of-One or very short runs, on the other hand, are not our market focus – although we do, of course, print run 1 books on special request or for urgent orders from our customers.”

Rodona co-owner and CEO Alberto Senosiain (right): “We produce exactly as many copies as customers need.” In the center, Ana Iribarren (Technical Department Manager); on the left, Juan Martin, After Sales Manager Muller Martini Ibérica.

Greater flexibility and quality

Because the extensive SigmaLine installed nine years ago with SigmaControl, SigmaFolder, SigmaCollator, SigmaBuffer, SewingCollator (especially for thread-sewed books) – with which Rodona has had good experience, according to Alberto Senosiain, and which has given him the reliable and fast service he wanted – was often at capacity, last May Rodona installed a SigmaLine III connected inline to an HP T250 digital press and controlled by the Connex workflow system. “With it,” says Ana Iribarren, technical department manager, “we have doubled our capacity. The new brilliant inks give us the opportunity to use even more types of paper and inks and to offer our customers – in addition to greater flexibility, especially with regard to deadlines – higher print and end product quality.”

Keyword customers: Rodona produces around 1.5 million books a year – 85 percent of which are for the Spanish market – primarily for a loyal base of major publishers. According to Alberto Senosiain, they enjoy several advantages thanks to inkjet digital printing.

- When a publisher publishes a new book, they usually don’t know how many copies they can sell. So he first tests the market with a smaller print run – and consequently has lower investment and initial costs than with offset.

- The production and delivery of both first editions and reprints and second editions of the same book take place in a very short time.

- Book production has changed – especially for products with a large number of pages, thin papers and high obsolescence such as legal or medical books that are constantly revised. The customer can have Rodona produce only the number of books he needs for a specific demand. Production and storage costs are lower, as are the costs, if any, of disposing of obsolete books. For example, we recently printed 300 copies of a 3.300-page medical book on 35-gram bible paper in just 24 hours and produced it on our Muller Martini Diamant bookline. This would not have been possible in the past at a reasonable cost and certainly not in such a short period of time.

- The newly developed folding systems from Muller Martini offer an expansion of the folding pattern spectrum and a reduction in white pages.”

“Postpress must keep pace with developments in the printing sector”

If Rodona mainly printed black-and-white books after going digital, color printing has taken off markedly in recent years – not least thanks to the additional paper grades. “That’s why it’s all the more important,” stresses Ana Iribarren, “that the development of finishing systems keeps pace with progress in the printing sector.”

Especially since one of Rodona’s specialties are thread-sewn, folded hardcover products produced on a Ventura, also from Muller Martini. The advantages of the new SigmaLine III come at just the right time for the company. Thanks to its innovative air knife technology, it now also enables variable folding. Whereas folding on the SigmaLine was previously done with a mechanical knife, the fold is now triggered by an air pressure pulse. Thanks to the air knife, production is much more stable at high speeds. The fold becomes more perfect, there are fewer stoppers, and production speeds increase up to 1.000 feet or 305 meters per minute – which is the highest output of digitally produced book blocks on the market.

Air knife technology also offers expanded production capabilities thanks to its variability. Several printed sheets can be pre-gathered in the longitudinal folder to form a book binding sheet. This allows several separate signatures to be combined into a single signature. For example, three 8-page signatures become one 24-page signature – an ideal pre-product for thread or saddle stitching.

Now with two SigmaLine digital book block systems from Muller Martini, Rodona is underpinning its leading position in the Spanish digital market.

Fewer white pages

Another great new feature is the dynamic trimming mode. Until now, the trimming/perforating/cutting process always resulted in a cross fold. Now the SigmaLine III can cut twice in succession. This means that the cross fold can be by-passed. The page divisibility of the book blocks can now be halved thanks to the dynamic mode, so there are fewer blank pages. Previously, it could happen that a sheet of 16 had up to 15 blank pages. Now there are sheets of 8 with a maximum of 7 blank pages.

The reduction in white pages is important not only in view of a considerably better final form of the book, but also in terms of sustainability. “Ecological awareness has taken hold,” says Alberto Senosiain, “in the graphic arts industry, and green issues are coming up more and more in customer contacts.”

Inline is more effective than roll/reel

As on the first line, Rodona also produces inline on the SigmaLine III. “This is much more effective than a roll/reel solution,” says Alberto Senosiain. “Since we specialize in lightweight papers, roll/reel would not be ideal for a lot of our products that need to be folded immediately after printing. In addition, I believe that precise folding and inserting on the SigmaLine is much better suited for thread-sewn, bound and hardcover products than cutting and then folding and stacking sheets.”

For the company patron, there is no doubt: “The future looks promising for web inkjet printing. After all, we can see the growth trend in the USA, which will certainly also take hold in Europe. I’m confident we’ll continue to be at the forefront of digital printing in Spain – even though our company’s growth may be slowed somewhat as a result of the corona pandemic.”

Learn more about Muller Martini’s digital book block system in the blog “From Black Box to Multifunctional SigmaLine III” on the Muller Martini website.

Read in this article how Core Publishing, an American customer belonging to the Thomson Reuters Group, optimizes its digital book production with the SigmaLine III.

This text is reproduced with kind permission of Müller Martini, you can read the original article first published here