Many of our customers today are faced with the task of making their conventionally run businesses fit for the digital world. As a workflow specialist, I have gained experience in many exciting projects. Using an example, I’ll explain to you in this blog how digital transformation can work.

The initial situation of my example customer was as follows: A printing volume of 800,000 books per year with an average daily production of 1,800 books. In the high season, it’s up to 4,500 books per day, of which up to 80 percent are produced in runs of one. The products ordered in the online web shop and on-demand are printed fully digitally. It’s quite clear here that highly automated and networked processes are needed in order to produce economically.

Highly automated equipment

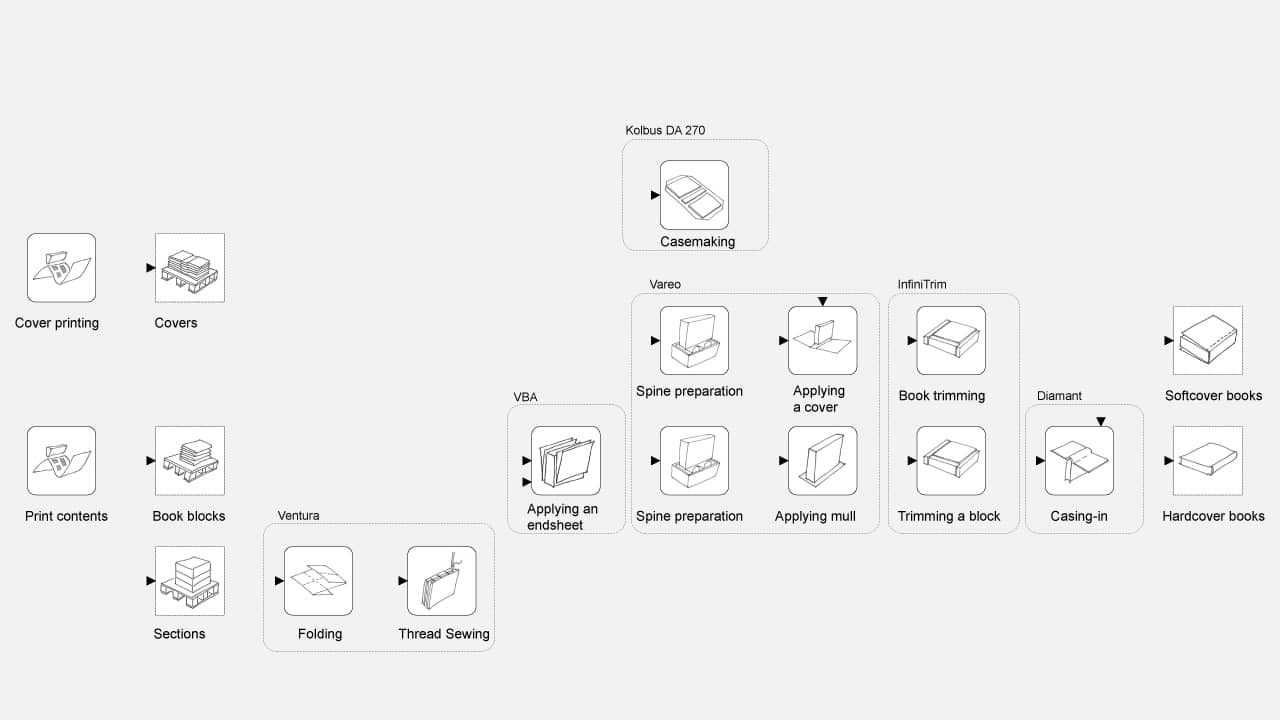

But before we look at the workflow, let’s talk briefly about the equipment. The basis for a networked printing plant is, of course, highly automated production systems that can implement the networked processes and workflows. In my example, we are talking about a digital printing plant with two digital printing presses. Since the company focuses on hard- and softcover products, the Vareo/InfiniTrim endsheet feeder solution is exactly right. It’s a hybrid system for softcover and hardcover, ensures automatic signature infeed, provides high size variability, and reduces manual interventions – just as described by Muller Martini in its Finishing 4 strategy. The system is supplemented by a Ventura MC Digital thread sewing machine, a Diamant MC Digital bookline from Muller Martini and a DA 270 casemaker from Kolbus.

More flexibility

Before our highly automated solution went live at the company, the printing plant worked with several less automated solutions. That meant book-of-one productions – particularly hardcover products – often involved a great deal of manual work because of the various production steps involved. Especially in seasonally fluctuating business – such as at Christmas – there was no flexibility to react to rapidly changing order situations. A scalable and highly automated solution was therefore required. With the new system, not only the softcover but also the entire hardcover process is fully automated. Loose or thread-sewn blocks are prepared in the Vareo cell and can be completed directly from the InfiniTrim three-knife trimmer in the Diamant MC Digital bookline to form hardcover books with round or straight spines.

Workflow Solution

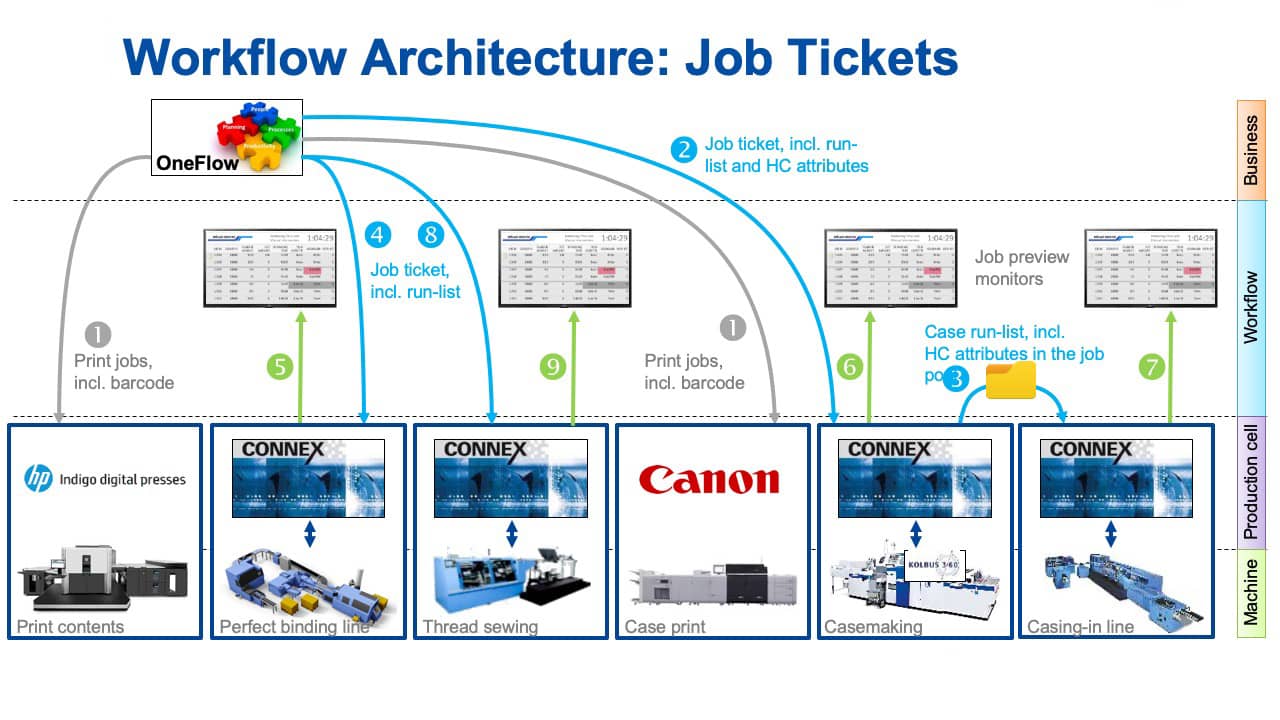

But let us now finally come to the workflow solution: This is of course crucial for the success of a smart factory. The customer’s aim was to transform the digital printing plant with finishing into an innovative smart factory. He wanted the highest possible level of networking and maximum automation from prepress to finishing, with the highest possible net output and the lowest possible use of personnel. A key point for the workflow design was to consistently avoid possible sources of operating errors. A lot of superlatives that needed to be covered! With the Connex workflow system, we developed an integrated solution for the customer.

How Connex works

First to the basics: Connex ensures networking between the company level (MES/MIS) and the production level. In a downward direction, order tickets with the required format and product parameters and, if required, the exact production lists are transmitted to the machines. Operating data collection takes place from bottom to top and is centrally managed via Connex.Info 4.0. Online evaluations are also possible via Connex.Info 4.0.

Data Flow via Barcode

Jobs are controlled via barcodes. The sections fed to the Ventura MC Digital thread sewing machine contain barcodes which are compared with the jobs loaded by Connex. The machine sets itself up semi-automatically and, based on the barcodes, can also process book blocks of variable thickness without interruption. Based on the barcode data, the composition of the book blocks is controlled and the sequence and completeness are checked. Connex continuously updates the production run lists and prints a material dispatch note at the end of an order.

Production on the Vareo perfect binder line with the endsheet feeder and the InfiniTrim three-knife trimmer, on the other hand, are controlled directly via barcodes. The order tickets and production run lists are used in this cell for order previews and the automatic printout of material dispatch notes.

Barcodes on Cases

Casemaking works in a similar way. The appropriate production templates are automatically loaded via barcodes on the case covers. Connex compares the feedback from the produced cases with the production run lists and notes if any cases are missing or if there are any sequence errors on the material dispatch notes. Of course, the operator can also intervene manually, for example, to subsequently log out any cases.

The exact casing-in sequence is crucial for the reliable and efficient operation of the Diamant MC Digital bookline. As soon as a casing-in batch is complete, the job folder and the corresponding production run list are automatically forwarded to the Diamant MC Digital. On the Diamant MC Digital, the order is loaded by scanning the material dispatch note and transmitted to the machine. The Diamant MC Digital then adjusts itself semi-automatically to the format data.

All four of our customer’s production cells continuously report back data to Connex.Info 4.0, which is directly forwarded to the customer’s MIS. If there are any bad or missing products, the MIS/MES can immediately initiate reprints. This enables the customer to optimally align his repair strategies – the planning and execution of reprints in the event of production waste – with his operational needs. The extensive online evaluations and the predefined reports that are automatically generated and sent in Connex.Info 4.0 are also appreciated.

Standardizing Positions

Our example customer has highly branched process chains, which is why the products and partial products pass through different processing stations depending on the type of production. It was therefore particularly important to include the necessary identification and control information in the barcodes for all workflow-supported production types.

Another thing we had to consider for the workflow solution was that the cameras are mounted at different positions on the respective machines. Therefore, barcodes on the book block, cover and the book case have to be printed several times and in different areas. In order to reduce unnecessary plurality at this point (printing, preparation effort and saving paper), it was important to standardize barcode positions in this project.

That’s why we created a cross-machine, project-related document with all customer-specific workflow specifications and discussed and clarified this with the customer in advance. Because the reliable reading of barcodes – or in this case mainly Data Matrix codes – is crucial for productivity. Any misreading leads to a stop or potential disturbance in the process. Accordingly, it’s necessary to carefully define which data are really necessary. The more compact the code is, the more reliably it can be read.

Order previews

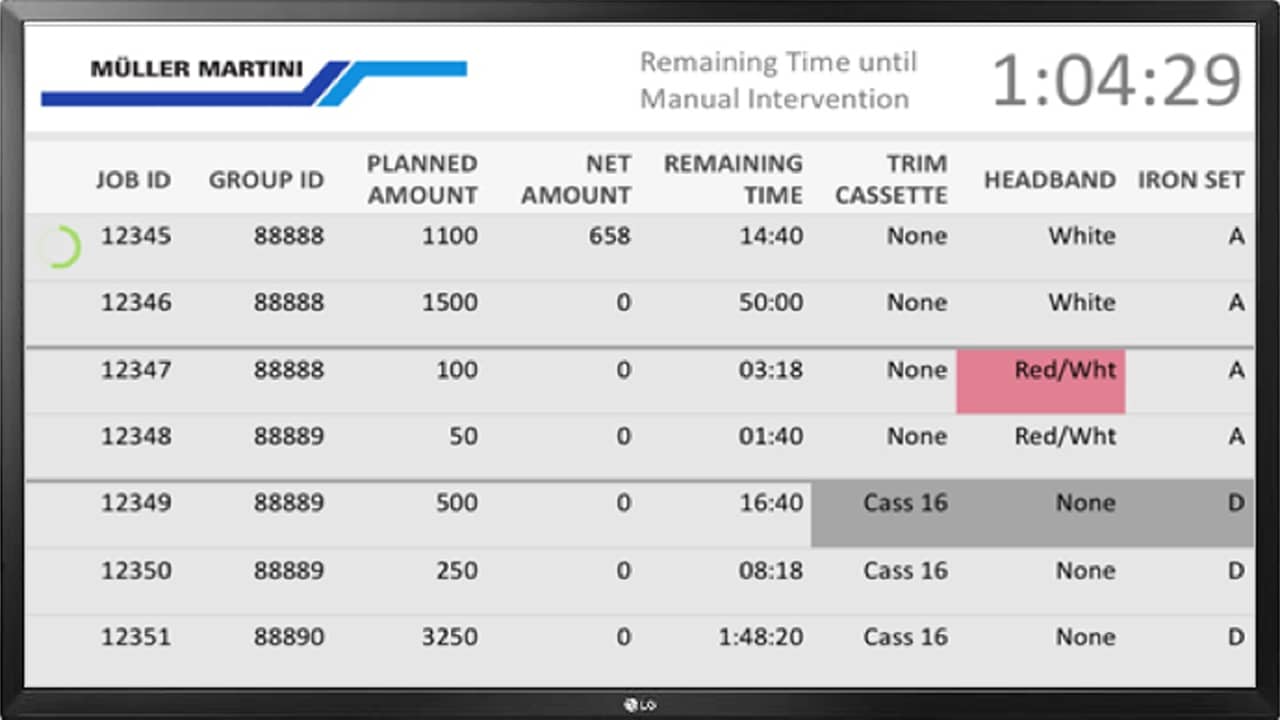

Finally, a note on waiting times. In order to be able to produce economically, it is essential to avoid waiting times. We have therefore developed a solution that uses the extensive information already available in the workflow system to visualize upcoming job changes for the operators as early as possible.

Colored highlighting shows where and when manual intervention is necessary. The operators can already prepare themselves for this while production is still running. Required exchange parts or tools can thus be made available at an early stage. Displays can be flexibly configured and operators can decide for themselves how they should be displayed.

This brings us to the end of this short excursion into the fascinating world of digital workflow. I hope you’re not overwhelmed by the many technical details. This should certainly not deter or prevent you from thinking about a digital workflow in your company now. We workflow specialists at Muller Martini have so far found a solution for every customer. This example illustrates how individual such solutions are. So: contact us, we’ll find a perfect workflow for you too.

And if you would first like more in-depth information about digital transformation and our ideas on the smart factory, I recommend reading our white paper.

Best regards,

Markus Bracher,

Head of Solutions Engineering

Muller Martini

This text is reproduced with kind permission of Müller Martini, you can read the original article first published here.